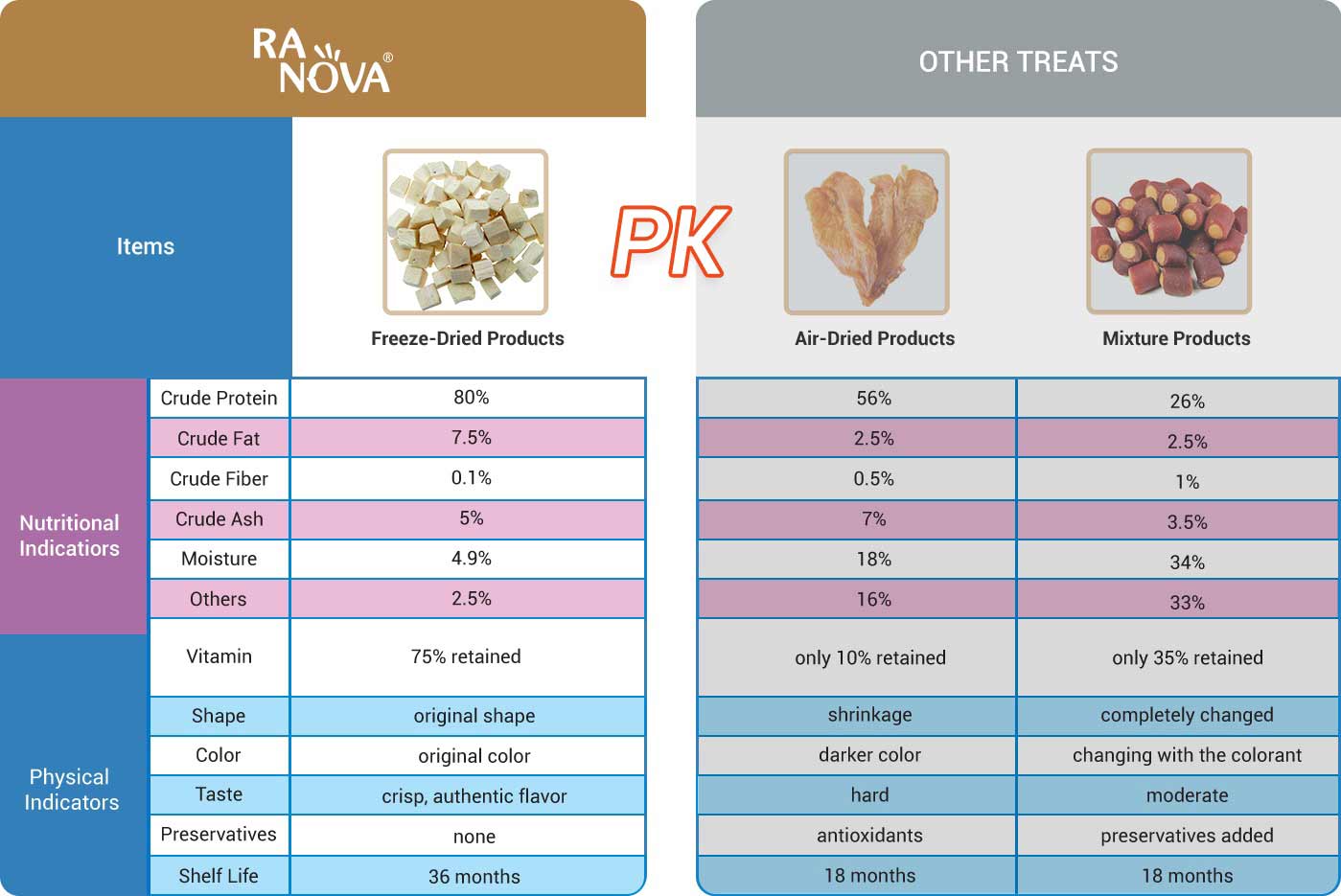

Freeze Dried Raw Food Advantages

Continuing the purity of raw materials, strictly implementing human edible standards

Made of pure meat, good palatability, no additives.

Keep the fresh and characteristic products of the ingredients easy to digest and absorb.

High nutritional protein content up to 80%.

Pasteurization & Radiation Sterilization Product Safety

Freeze-drying process for long-lasting quality without preservatives.

Freeze Dried Pet Treats Comparing

Freeze-drying Process of Pet Food and Treats

Fresh pure meat is chosen and cut into pieces without applying any other ingredients, while the fat, skin and bones are removed.

Freeze the meat at -32℃ to retain its nutrition.

Vacuum freeze-drying for 18 to 36 hours to sublimate its water, raising temperature to 90℃ for sterilization, completing the entire freeze-drying process.

Select qualified semi-finished products and remove the imperfect ones.

Package finished products, irradiate them for sterilization